ASPIRE TOWER

This

document covers the Parametric modeling of the Aspire tower in Doha. This tower

was designed by the architect Hadi Simaan, as a representation for the

celebration of earth and sky. This tower was significant due to its proximity

to the main venue, the Khalifa International Stadium which hosted the 15th

Asian games at Qatar.

|

|

Figure depicting the Aspire Tower in Doha (Source: Google Images)

Modeling Process

The

model was split into two components. The first component comprised the design

of the main structure into which the torch component too was added. This hosted

several different features like 5 Star Hotel, Presidential Suites, Swimming

pool, Health club among several other features in 36 floors. The second

component involved designing the lattice structure that encompassed the torch.

The

first component was made parametric by varying two key parameters: The height

of the concrete core and the radius of the bottom floor. The subsequent floors

were made to vary parametrically based on the bottom radius. These floors were

in turn made to vary parametrically in their relative elevation from the

ground. This was achieved by fixing their heights with respect to the height of

the concrete core. This made possible to both vary the height and shape of the

model without compromising the design intent of the architect, whose primary

motive was to make this structure resemble that of a colossal torch.

Reference

planes were created at different elevations to form a parametrically driven

conceptual mass. By varying, the key parameters it was possible to make the

model assume different shapes, keeping in mind the design intent of the

architect.

Concrete Core Creation

The

first step was to create a concrete core that acts as support structure for the

other components. The concrete core had an internal and external diameter that

varied throughout its height. So, to fix this aspect, the midpoint of core was

kept as the point of minimum diameter and this dimension was varied across the

total height in order to create a tapering effect to the design. The external

diameter varied between 43 feet to 60 feet with thickness varying between 3 to

6 feet. This made possible to fix the eternal diameter at midpoint to 43 feet

and the bottom external diameter to 60 feet. The internal diameter was 3 and 6

feet respectively. The top portion corresponding to the end point of the

concrete core was assigned as the mean of these two parameters. The form was

then created as shown in Figure 1.

Modeling of structure features

As

mentioned previously the structure hosted different features across its heights

and thus it was of importance to plan the number of floors for each of these

features. The floor distribution is as shown in table 1. The height between

each floor was fixed to 10 feet and this is explained in Mass Modeling revit

file. Figure 1 also depicts circles of different diameters, which were

primarily controlled by taking appropriate dimension ratios. It was important

to find the right ratio else the structure could have possibly assumed

different shape.

Serial No.

|

Feature

|

Number of Floors

|

1

|

Large

Reception and Public Area

|

2

|

2

|

5

Star Hotel

|

17

|

3

|

Sports

Museum

|

3

|

4

|

Health

Club

|

4

|

5

|

Presidential

Suites

|

3

|

6

|

Observation

Desk & Revolving Restaurant

|

7

|

Table 1: Floor distribution for each of the features

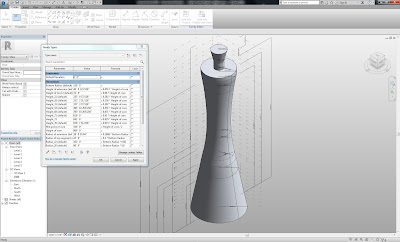

Figure 1: Figure depicts central concrete core and

creation of parametric circles

Creation of form elements to host

different features

The

next step was to create form elements that when put together would represent

the actual structure. This is shown in Figure 2. As it can be observed in the

figure, the structure is again of tapering design as mentioned previously. The

achieved results was in good correlation to the actual structure design. Each

of these forms were made to vary parametrically by fixing their height and

diameter to vary parametrically with that of the key parameters mentioned

previously. These form elements were made to host the different features

bearing their support from the central concrete core.

Figure 2: Creation of form elements that exactly

resemble the actual structure

Creation of extension to place torch

Another

observation made during data collection was that the torch was not directly

placed on the upper level of the structure. Rather, an extension that

originates at the upper level from the concrete core forms a support to hold

the torch. The diameter and height of this extension was again made to be

parametrically driven by key parameters and is illustrated in figure 3.

Creation of Torch

The

torch is then finally placed on this extension to complete the first component

of the design. The design of the torch is in the form of frustum of cone and

made to vary parametrically too. Figure 4 shows the d first component with

torch. The height of torch was fixed at 62 feet.

Design of Lattice structure

The

next part of the design comprised of designing the lattice shell structure that

housed the torch. After some trials, the design was incorporated by cutting an

ellipse geometry from a hollow cylinder that best closely resembled the actual

structural design. This structure was created as a separate conceptual mass

which was later integrated into the first component design to complete the

design. The lattice structure radius was defined as an instance parameter which

was then associated to the Radius of the top most surface of the first

component in order to create a parametric design. This association allowed to

achieve some desirable effects though led to some complications as discussed

later. This is shown in figure 5.

Figure 3: Creation of extension that host the torch

Figure 4: Shows placement of torch

Figure 5: Design of lattice shell structure

Completed first component

From

figure 4, the model form was created which finally completed the first

component design.

Figure 6: Completed first component

Completed whole structure

The

lattice shell structure was then placed on top of the completed first component

to give the whole parametric model of the structure as shown below. It was

found to be in good correlation with the actual structure design.

Figure 7: Aspire Tower Parametric completed model

FORMULAS USED

The whole parametric

modeling was done to good judgement of the actual structure design. The

formulas are as shown below.

Figure 8: Formulas Used

Parametrically controlled mass

Varying the key parameters was able to give new shapes to the structure. Some of the shapes generated by varying the height of core and the Bottom Radius are as shown below.

Figure 9: Parametric model creation

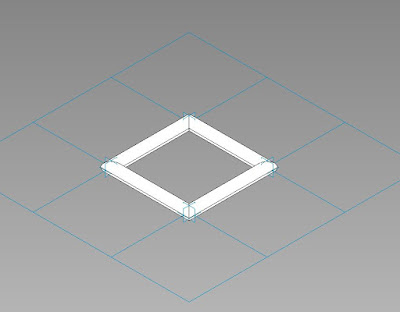

Facade Pattern for Building Mass

Parametric building facade pattern is created for the model by creating individual components for the first component and the second component. Total of four facade patterns were created. The first component hosted two of these patterns. The patterns are as shown below.

Figure 10: Facade patterns for first component

The completed building mass hosting these patterns is as shown below.

Figure 11: First component with facade patterns

The second component again hosted two facade patterns. The interior and the exterior surfaces of the mass were made to host different patterns. The interior pattern shape resembled that of rhomboid and the exterior patterns resembled that of a rectangle. These are depicted in the images shown below.

Figure 12: Facade Patterns for second component

These facade patterns were then hosted along the interior and exterior surfaces to create the lattice shell structure that hosted the torch.

Figure 13: Creation of lattice shell structure

The lattice shell structure was then combined with the first component of the structure to create the Aspire Tower model.

Figure 14: Aspire Tower Model

Massing

This building model was then loaded into a new project to create mass floors and roofs. The floor distribution in each of the feature is as mentioned above. After creation of the floors and roofs, interior designing was done for two features, namely the revolving restaurant and a model of the 5 star hotel room. (This was my intention but I am really not sure if the rendering images below suggest the same. So please bear with me :))

Rendering

For the rendering elements, toposurface was created. Pads are created in an effect to show the foundation effect for this structure. To this, road elements and environmental elements were later added.

Exterior Rendering

Some of the exterior rendering images are as shown below.

Interior Rendering

The interior rendering images are shown for different times of the day. There are two features modeled in the interior renderings.

Hotel Room Rendering

Hotel Room Rendering late afternoon

Hotel Room Rendering night time

Restaurant Waiting Area

Waiting Room close to sunset

Waiting Room during night

During Day

Problems Encountered

During the placing of the lattice structure on the first component, even after associating the parameters in the nested family, I was not able to modify or vary the structure parametrically for the Bottom Radius key parameter. The model however works fine when height of core is varied. Also, custom pattern 1 is not able to adjust parametrically with the tower. These problems will be corrected in the subsequent project.

Project Video

References

3. Miscellaneous information and gallery, https://en.wikiarquitectura.com/index.php/Aspire_Tower

4. Google Images

HI VALAPADI . I'm from turkey and I am arc student. I need this project structure modelling for my carrier systems course . Can you help me pls . I need so much pls help me contect me pls . I l wait your comment pls help me :(((((((((((88888

ReplyDelete